ELSIE conducted an industry survey to assess current practices, challenges, and strategies for physicochemical testing compliance in response to the upcoming USP <661.2> regulations for plastic container closure systems

The survey collected insights from pharmaceutical, biopharmaceutical, and nutraceutical professionals on testing methodologies, frequency, and the role of these tests in supporting extractable and leachable (E&L) studies and safety assessments for various risk levels

Analysis aims to provide an overview of organizational compliance strategies, identify barriers, and evaluate the use of E&L data as alternatives, ultimately guiding best practices and innovations in plastic packaging qualification.

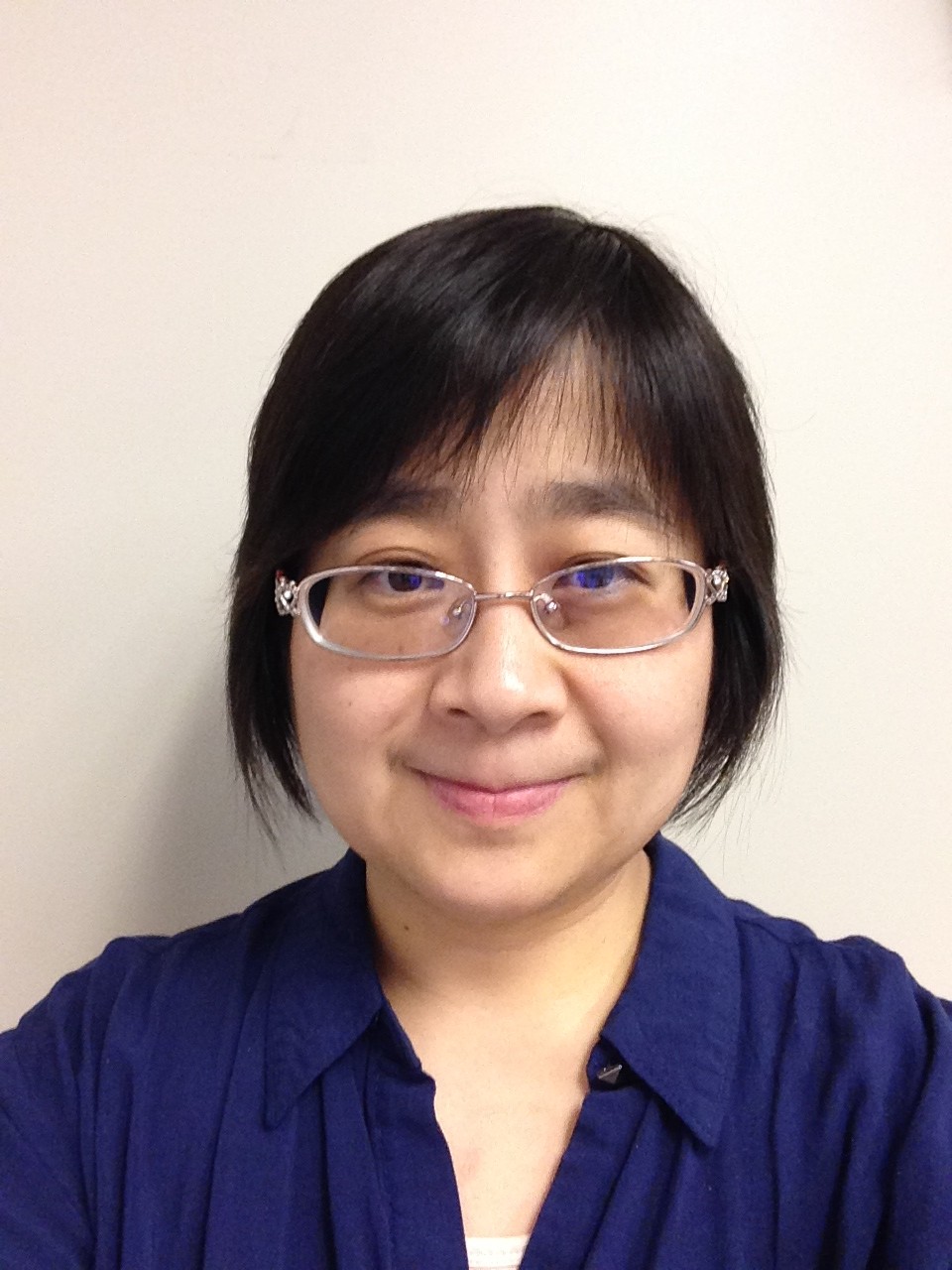

Yemin Liu | Sr. Principal Research Scientist, AbbVie

.png?ext=.png)